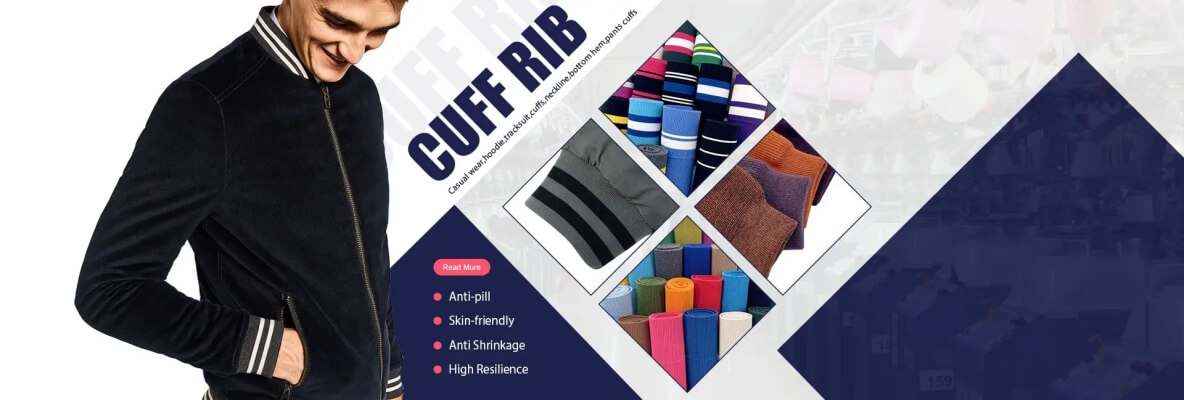

Custom height and length, it normally used for hoodie, jacket, sportswear, down jacket, cuffs and waist band, wrestling singlet leg cuffs, rib knit hem, Any color and measurement are available.

Item No :

YM2023N1218Order(MOQ) :

500Product Origin :

chinaColor :

green, red, blue, whiteShipping Port :

shenzhenWeight :

800 g

Polyester knit ribs with green, red and white stripes are a versatile material that is often used on the cuffs and hem of jackets and casual wear. Its design is flexible and different materials can be selected according to customer requirements. Polyester is a synthetic fiber that has excellent durability and wrinkle resistance, while also being easy to maintain and clean. Rib weaving gives this striped material better elasticity and stretch, making it a more comfortable fit. The design of green, red and white stripes is elegant and unique, and can be matched with many different colors, making it very widely used in clothing. Customers can choose a combination of different materials according to their needs to meet individual requirements. These stripes are often used to embellish cuffs and hem, adding a touch of pizzazz and style to an outfit.

| Model Number: | YM2023N1218 |

| Weaving process: | Flat Knitting Machine |

| Needle: | 12 needles |

| Weave : | 2X1 |

| Yarn count: | 32 s |

| Specification: | collar cuff hem |

| Composition: | 97% polyester 3% spandex |

| Width: | 80 CM*15.2 CM |

| Gram weight: | 800 g |

| Can be used on: | Jacket, padded jacket sport casual wear, children's wear |

Our Advantage:

Over 12 years of manufacturing experience, strong production scale, competitive price, strict high quality control, and professional sales team with fast service.

1 Incoming inspection

Appearance Quality :Check quality indicators such as flying yarn, oil stains, color difference, yellow spots, color fastness, etc.

Intrinsic quality :100% inspection on every color.

2 First product inspection

The first product is produced according to the mass production process, Bulk commodities can be produced only after approval.

3 Production inspection

first part :Quality checks, controls and records are performed every 30 minutes.

the second part :Real-time detection of each piece after weaving provides timely feedback on quality information.

the third part :Each finished product is inspected in real time after completion. Timely feedback of quality information.

4 Pre-shipment inspection

Each package must be inspected before packaging to ensure that the product is 100% qualified before it can be packaged and shipped.

5 Internal testing center

Equipped with consistent testing equipment from the National Testing Center and certified qualified inspectors, each color is tested in-house. The items include: 5A3 water washing, friction resistance, color migration resistance, water resistance, soap resistance, perspiration color fastness and formaldehyde resistance. Assay, pH, odor chemical testing.

6 Customer service

Conduct customer satisfaction surveys every quarter to collect opinions for review and improvement. Carrying the service concept of customer first, exceeding customer satisfaction, and providing customers with high-quality services.

Product Advantage:

1. Care for your health by using high quality brand new raw material.

2. Good fitting with smooth surface.

3. High tenacity performance to fit all your needs.

4. Competitive price from manufacturer.

5. Any color, any sizes, any logo can be made by the request of customers.

Tags :